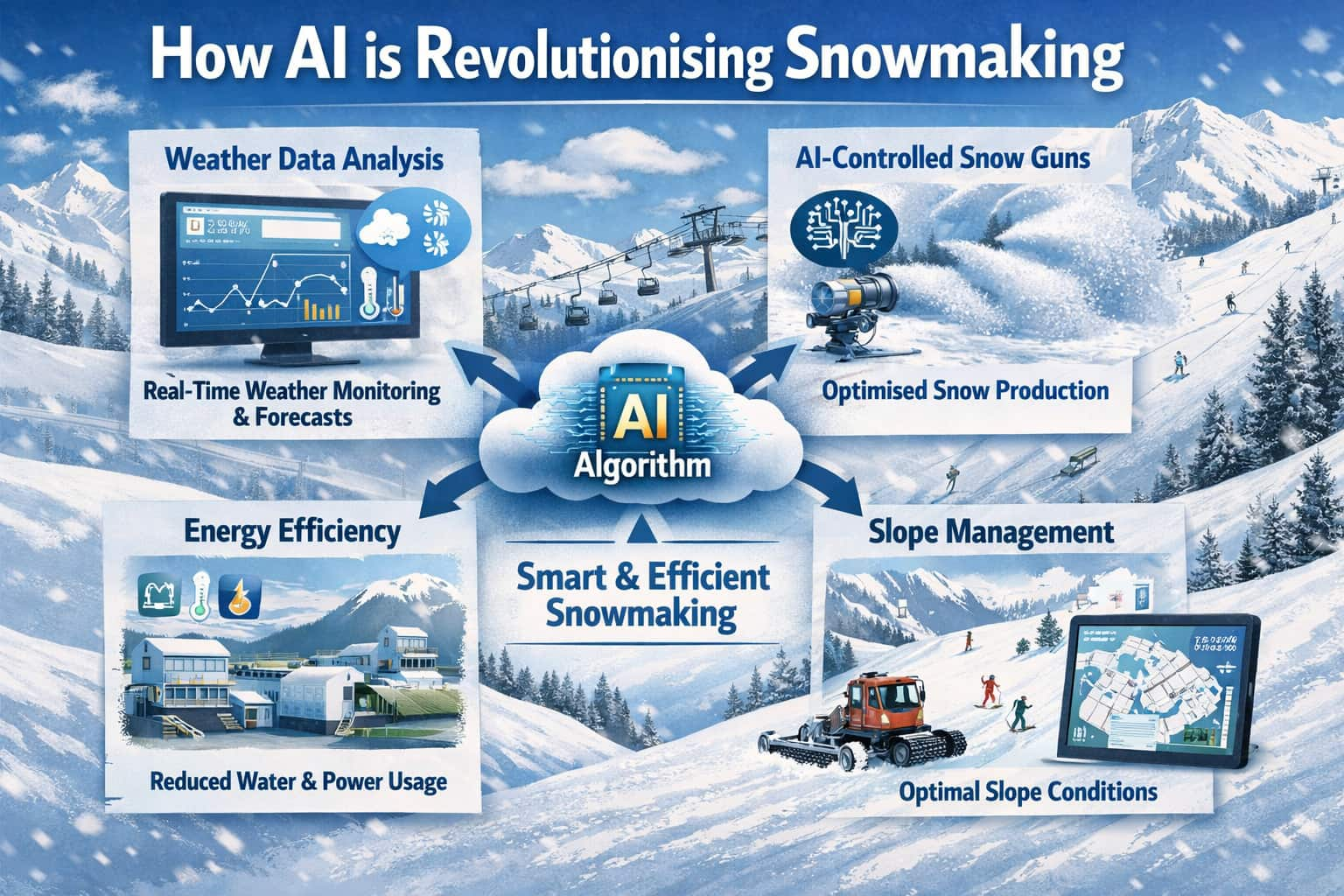

How AI is Revolutionising Snowmaking: The Technology Keeping Ski Resorts Alive

Picture this: a French ski resort making artificial snow when the temperature hits 10°C. Sounds impossible? Welcome to Super-Besse in the Auvergne region, where AI-powered snowmaking systems analyse weather data to identify brief optimal windows for production, preparing pistes with a 30-meter-wide snow layer even in seemingly unfavourable conditions.

Or consider Mountain Creek in New Jersey, which slashed energy consumption by 70% while doubling snow output—now running 15% of their system for the same cost it once took to operate just 1% of the old manual setup. This isn’t science fiction. It’s the new reality of ski resort operations, where artificial intelligence is transforming snowmaking from an energy-intensive gamble into a precise, efficient science.

The Magic Number: -3°C Wet Bulb Temperature

At the heart of AI snowmaking lies a critical threshold: approximately -3 °C wet bulb temperature. This measurement combines air temperature with relative humidity into a single metric that determines when water droplets can freeze into snow crystals. Traditional operators relied on experience and manual checks, often missing short production windows or running equipment when conditions were suboptimal. Today’s automated systems monitor wet bulb temperature in hourly intervals with updates every two hours, analysing real-time data from weather sensors that track air temperature, relative humidity, barometric pressure, wind speed and direction, solar radiation, and precipitation.

These AI platforms can identify snowmaking opportunities as brief as a few hours in advance, sometimes detecting temperature inversions as they occur or even before they happen.

At Levi Ski Resort in Finland, 335 automated snow guns equipped with weather sensors continuously adjust water pressure and flow rates based on these conditions, with the same amount of water and energy producing significantly more snow today than five years ago. The system ensures guns activate only when all factors align—proper temperature, wind direction, and humidity—achieving up to 30% savings in water and electricity consumption per section over an entire season.

Mountain Creek’s Transformation: From Energy Drain to Efficiency Leader

Mountain Creek‘s journey illustrates the dramatic impact of AI automation. The New Jersey resort invested in TechnoAlpin automated fan guns, replacing a legacy system where a single old air/water gun consumed as much energy as six new automated units. The transformation delivered staggering results: 70% reduction in energy consumption while producing twice the output compared to the manual system.

The financial implications are equally impressive. Mountain Creek now operates 15% of its new system for the same cost it once took to run just 1% of the old system. Beyond equipment efficiency, the automated system’s ability to quickly start up and shut down allows the resort to “dance around demand charges more nimbly”—avoiding peak electricity pricing periods that can multiply energy costs. The underground infrastructure and automated controls improved operational efficiency and the guest experience, eliminating the maze of hoses and equipment that once cluttered the slopes.

Similarly, Giants Ridge in Minnesota invested $14 million in an SMI automated system covering 62% of its terrain, cutting total snowmaking hours from 751 to 532 in the first season—a reduction that translated to $200,000 in electricity savings. The automated system eliminated the need to manually move hoses and equipment around the mountain, also saving significant fuel costs through reduced snowcat hours.

How the Technology Actually Works: Sensors, LiDAR, and Smart Decisions

The backbone of AI snowmaking is a comprehensive sensor network that feeds real-time data into centralised control platforms. GPS-equipped LiDAR sensors mounted on grooming machines take up to 200,000 measurements per second, scanning terrain up to 50 meters ahead and measuring snow depth with centimetre-level accuracy. This data is displayed in the groomer cab using colour-coded visualisation, where different colours represent varying snow depths, allowing operators to identify low-snow areas at a glance.

At resorts like Val Thorens in the French Alps, this snow depth data links directly to snow guns, allowing them to automatically produce artificial snow in an intelligent manner based on GPS measurements. The system identifies exactly which slope sections require additional coverage, preventing overproduction and optimising water and energy consumption. Laax in Switzerland has taken this integration further with LEITNER’s Skadii system, achieving a 10% reduction in artificial snow requirements while maintaining superior slope conditions.

Magnetic flowmeters with EtherNet/IP connectivity measure water flow from pumps to snow cannons, while pressure transmitters continuously monitor operating pressure throughout the system and automatically adjust flow rates based on current conditions. Modern machine rooms utilise IO-Link communication technology that digitally transmits all sensor readings, providing far more information at faster speeds than legacy analogue systems while instantly relaying fault information for predictive maintenance.

The Future: AI Becomes Standard Across the European Alps

The success stories are driving rapid adoption across the ski industry. The French manufacturer MND announced that beginning in 2026, it would integrate AI into all engineering processes for mountain mobility and snowmaking infrastructure. French ski resorts maintain approximately 45% terrain coverage with artificial snowmaking systems, and many now use platforms like SNOWsat or LEITNER’s Skadii for slope grooming and snow management—technologies that North American resorts in Canada and the U.S. are increasingly adopting.

Les Sybelles ski area in the French Alps has implemented comprehensive AI systems with most chairlifts equipped with optimisation technology, achieving 15-20% fuel savings for groomers and reduced artificial snow requirements. As climate can affect natural snowfall, AI-powered snowmaking has evolved from a competitive advantage to an operational necessity—the difference between opening on schedule or watching the season slip away.

Quick search

Allemond, Alpe d’Huez | Cœur Massif

You can contact via phone: mobile: Please use the #%id to identify the property "Allemond, Alpe d’Huez | Cœur Massif"

Oz, Alpe d’Huez | Les Balcons d’Argent

You can contact Domosno via phone: +44 79 0100 2763 mobile: Please use the #%id to identify the property "Oz, Alpe d’Huez | Les Balcons d’Argent"

Bourg-Saint-Maurice Les Arcs | Pure Lodge

You can contact Domosno via phone: +44 79 0100 2763 mobile: Please use the #%id to identify the property "Bourg-Saint-Maurice Les Arcs | Pure Lodge"

Thinking of buying in the French Alps?

Save time. Tell us your requirements, and our local advisors will curate a shortlist of the finest ski properties for you—including exclusive off-market listings.

Domosno — member of the

Association of International Property Professionals

since 2010